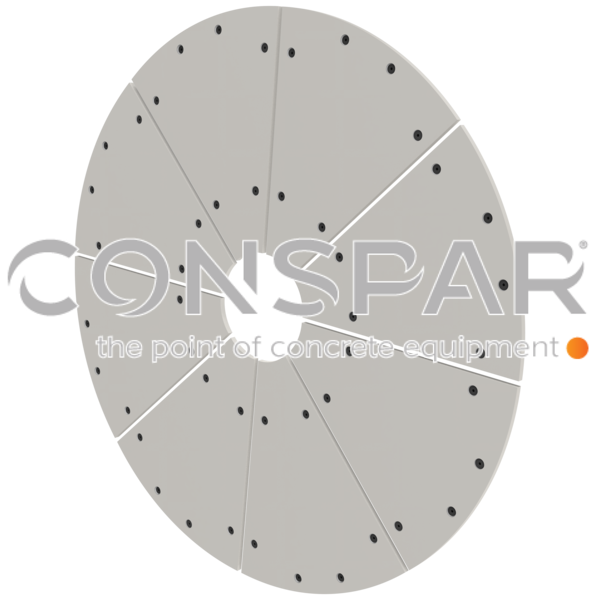

Wear Plates for Concrete Mixers

Explore our range of wear plates and wear parts for concrete mixers to protect the concrete mixing machine from abrasion and wear. High-quality and durable solutions for concrete mixing technology.

Concrete Mixer Machinery

The Role of Wear Plates in Concrete Mixing Technology

Wear Plates in Concrete Mixing Technology : A Solid Protection Against Abrasion and Wear

The primary role of wear plates is to protect the concrete mixers' internals against abrasion since the Concrete mix involves aggregate materials like sand, gravel, and rocks, known for their abrasive nature. These abrasive materials would quickly erode the concrete mixer's internal surfaces without wear plates. Thanks to the design of wear plates, the mixer's interior parts are protected from the harm caused by the mixing process.

Maintenance and Replacement

When the importance of concrete mixers such as single-shaft concrete mixers or twin-shaft concrete mixers are considered for concrete Production machines like mobile concrete batch plants or stationary concrete batching plants, regular inspection and maintenance, including replacing wear plates are essential for sustainable batching concrete. This routine extends to various models, including the Twin Shaft Mixer Liner Plates and Concrete Mixer Wear Plates, ensuring the mixer's effective operation.

Material of Construction

Wear plates, often made from hardened steel or other wear-resistant materials, including Steel Hardox when needed, are crucial in twin-shaft mixers and single-shaft concrete mixers. These materials are essential for withstanding the abrasive nature of the concrete mix in concrete mixing machines, prolonging the mixer's life in various settings like mobile concrete batching plants and concrete batching systems.

Conspar is your partner for sourcing the right fit: We provide wear plates for MEKA Concrete Mixers and CM Italy ( also known as CM costruzioni meccaniche) Mixer Wear Parts.

In conclusion, wear plates are indispensable in the concrete production process, offering protection, efficiency, and extended lifespan.